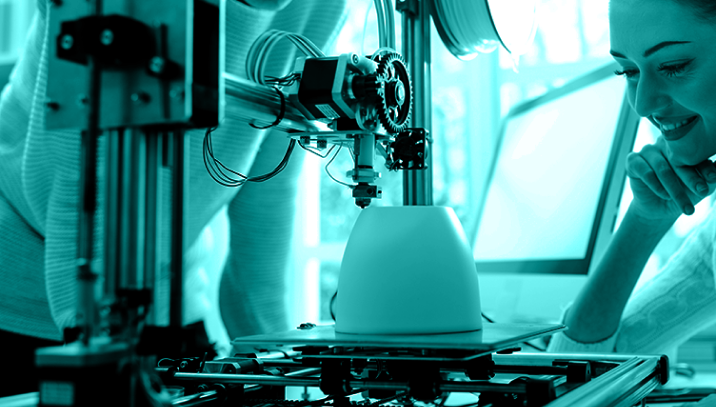

The integration of 3D printing technology is transforming the fashion and jewelry design process in innovative ways. With this advanced fabrication method, designers can now rapidly prototype and manufacture customized pieces with complex geometries and details that would be much more difficult or time-consuming to produce using traditional techniques. Using 3D printing can also improve sustainability, as items can be created on demand with minimal material waste.

Evolution and Methods of 3D Printing in Fashion and Jewelry

The earliest 3D printing technology emerged in the 1980s, but its adoption in fashion and jewelry design is quite recent. In the early 2000s, designers started using 3D printing methods like selective laser sintering to create unique jewelry pieces and accessories by fusing powdered material layer by layer. By 2010, major fashion brands had introduced 3D-printed shoes and apparel using techniques like fused deposition modeling, which extrudes heated plastic filament. Today, designers can employ a variety of printing methods, including stereolithography and multi-jet fusion, to produce customizable, geometrically complex fashion items and jewelry.

Benefits of 3D Printing in Design

By using 3D printing, designers and manufacturers can produce customized fashion and jewelry pieces for individual customers. Unlike traditional mass production, 3D printing enables on-demand production of personalized pieces tailored to each person’s taste and measurements. It can also speed up the design process in cases that require prototyping and refinements before the final product is created.

Additionally, 3D printing minimizes waste and environmental impacts by using only the required amount of material to make the product. This is a particular problem in the fashion industry, where mass production of clothing creates significant fabric waste as pieces are cut from whole cloth. These scraps typically end up landfills. But with 3D printing, you don’t need to consume more material than is necessary to make the product, and if you do have any scraps, they can often be easily re-used to make something else rather than thrown away.

Custom manufacturing through 3D printing can also have broader impacts on the environment due to the reduced need for inventory to be maintained. With on-demand production, manufacturers don’t need to maintain storage space for large amounts of stock or ship this stock across the country or around the world to retail stores. Likewise, retailers don’t have to create more harmful emissions by shipping unsold stock elsewhere to be trashed, incinerated, or repurposed at the end of the fashion season.

Outlook for 3D Printing in the Fashion Industry

As 3D printing technology continues advancing rapidly, its applications in fashion and jewelry are likely to grow. On the business side, 3D printing could disrupt traditional manufacturing and supply chains while making it easier for companies to sell highly customized products. This technology is also constantly improving, giving clothing and jewelry manufacturers the ability to work with more and better materials. Techniques like fused filament fabrication allow designs with eco-friendly, biodegradable materials like cellulose and bioplastics. Selective laser sintering can print durable elastomers and polyurethanes for flexible, high-performance athleticwear. Emerging techniques like multijet fusion printing allow the blending of colors and materials for smoother finishes. Cold metal 3D printing can produce jewelry from fine silver and gold at room temperature with precise details. And embedded electronics printed directly onto fabrics could even unlock smart clothing possibilities.

As material science and 3D printing methods evolve in tandem, the future looks bright for high-quality, sustainable fashion and jewelry created through digital fabrication.

- How 3D Printing Is Revolutionizing the Fashion Industry

- 3D Printing in Fashion: How Are 3D Printers Used in Fashion?

- How 3D Printing Is Reshaping the Luxury Fashion Industry

- 3D Printing Is Reshaping the Jewelry Business

- 3D Printing: From Imagination to Reality

- How 3D Printers Work

- 3D Printing and Its Environmental Implications

- Is 3D Printing the Future of Sustainable Manufacturing?

- Why Fashion Needs to Be More Sustainable

- How Sustainable Is 3D Printing?

- Appraisal and Insurance for Jewelers

- Will You Marry Me if I Ask With a 3D-Printed Ring?

- How Are 3D Printers Used in the Fashion Industry?

- Six Predictions for the Future of 3D Printing

- 3D Weaving Tech Could Mean Less Waste for Fashion Industry